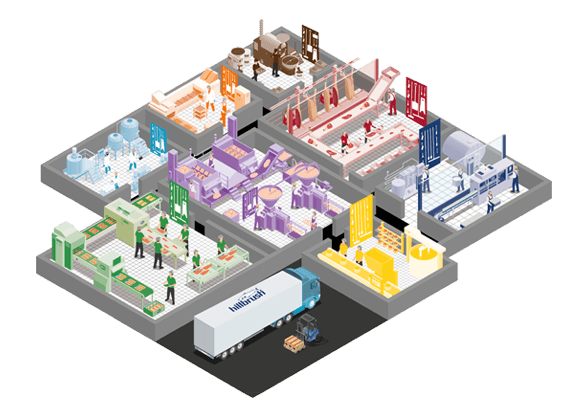

HACCP – Color coding

Color coding tools has become a recognised asset within good manufacturing practices in food and beverage production, proven to support segregation, improve visual standards of cleaning and support the identification of foreign body caused by wear and tear of cleaning and food contact tools.

Tools with matching-colored handles and heads can be identified quickly and easily, which is especially important within workplaces where several languages are spoken and can greatly aid the training of staff.

Segregation of activities is particularly important when managing:

- - Different levels of risk within manufacturing operations (high level, high care, and low risk)

- - Manufacture of allergens and non-allergens containing products, ensuring specific tools can be safely managed during use, cleaning, and storage.

- - Cross-contamination routes related to usage of equipment for cleaning and handling products.

- - Specific hazards: a methodical color-coded approach associates each product with a particular area, promoting inter-departmental and/or food-type segregation.

Most of our hygiene range is color coded, with up to twelve vibrant, easily identifiable colors to choose from.